Gas pressure vessels are designed to store gases at higher than atmospheric pressure and are used extensively across industries, including energy, manufacturing, and healthcare. These vessels must be carefully managed to maintain safe operation. A critical factor in their design and use is understanding how adding gas affects the pressure inside. This article will explore the relationship between the amount of gas added and the resulting pressure changes, as well as the role of temperature and safety measures essential for handling gas pressure vessels.

Pressure Increase with Added Gas

The internal pressure of a gas pressure vessel depends on the number of gas molecules present, which directly impacts the frequency and intensity of collisions between these molecules and the vessel's walls. According to the ideal gas law, ( PV = nRT ), where ( P ) is pressure, ( V ) is volume, ( n ) is the number of moles of gas, ( R ) is the gas constant, and ( T ) is temperature. When gas is added to a vessel without changing its volume, the number of gas molecules (( n )) increases, leading to higher pressure inside the vessel.

For example, in a sealed pressure vessel of fixed volume, adding more gas molecules increases the density of the gas. This causes more frequent collisions of gas particles with the vessel walls, thereby raising the internal pressure. The extent of the pressure increase depends on how much gas is added and other factors such as temperature.

The Impact of Temperature on Pressure

Temperature plays a crucial role in the pressure inside a gas vessel. When gas is added, the process may generate heat due to compression or friction, causing an increase in the temperature inside the vessel. According to Gay-Lussac's Law, pressure is directly proportional to temperature when volume is held constant. This means that if gas is added and temperature rises, the pressure will increase more significantly than if the temperature were kept constant.

In industrial applications, this temperature effect is managed carefully. For example, when gases are rapidly compressed into a vessel, they tend to heat up. If this heat is not dissipated, it can lead to an unexpected increase in pressure, posing risks to the integrity of the vessel. Cooling systems or heat exchangers are sometimes employed to regulate temperature and ensure the pressure remains within safe limits.

Real-World Applications of Pressure Management

Gas pressure vessels are used in many applications, from storing compressed air for pneumatic tools to holding natural gas for energy distribution. In all these uses, understanding how adding gas affects pressure helps ensure the safe design and operation of the vessels.

For instance, in the storage of liquefied natural gas (LNG), vessels must be designed to withstand high pressures without failing. The vessels are equipped with pressure gauges and monitoring systems that track changes in internal pressure as gas is added or consumed. Advanced pressure management systems can adjust the rate at which gas is added to prevent sudden pressure spikes.

In medical technology, such as oxygen tanks used in hospitals and emergency services, accurate pressure regulation is vital. Oxygen tanks must be filled and maintained in a way that considers how much pressure the addition of gas creates and how it affects the overall safety and functionality of the tank.

Safety Measures for Handling Pressure Increases

Handling gas pressure vessels safely requires understanding the limits of the materials and the design of the container. Vessels must be made of materials that can withstand the pressures involved, such as high-strength steel or composite materials. Regular inspection is essential to detect any wear, corrosion, or microfractures that could compromise the vessel's ability to contain high-pressure gas.

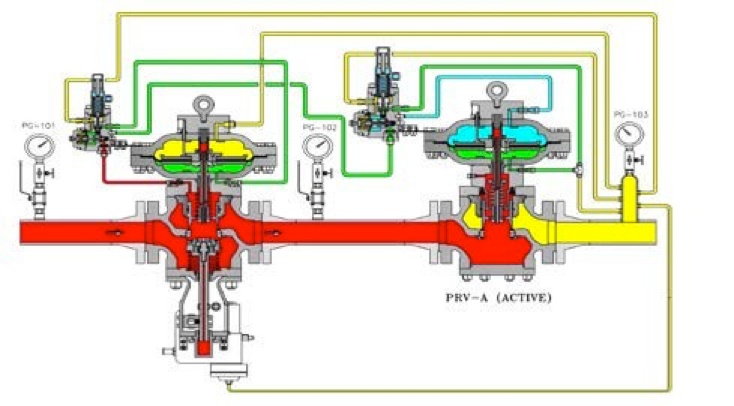

To mitigate the risks of overpressure, gas vessels are typically equipped with pressure relief devices, such as valves and rupture disks. These components are designed to release gas if the internal pressure exceeds a specific threshold, preventing damage to the vessel and surrounding equipment.

Operators also use pressure sensors and automated systems to monitor and control the pressure continuously. These systems ensure that the addition of gas does not lead to dangerous conditions, especially in high-pressure applications like industrial gas storage and transportation.

Adding gas to a pressure vessel increases the internal pressure due to the increased number of gas molecules colliding with the container walls. The process can be further complicated by temperature changes that amplify pressure variations. Understanding the principles of gas laws and incorporating safety features such as pressure relief devices and temperature controls are essential for safely managing gas pressure vessels. Whether used in industrial, medical, or commercial settings, a comprehensive approach to pressure management ensures the safe and effective use of these critical systems.